Mastering automatic transmission troubleshooting empowers drivers to identify and address issues early, ensuring safety, performance, and preventing costly repairs. This guide provides essential insights for effective problem-solving.

Importance of Early Identification of Transmission Issues

Early detection of transmission problems is crucial for preventing minor issues from escalating into costly repairs. Identifying symptoms like slipping, unusual noises, or fluid leaks promptly can save time and money. Addressing these issues early ensures smoother performance, improves fuel efficiency, and enhances safety; Neglecting early signs can lead to severe damage, requiring extensive and expensive overhauls. Regular checks and timely interventions are key to maintaining optimal transmission health.

Overview of Common Transmission Problems

Automatic transmissions often face issues such as fluid leaks, slipping gears, and delayed engagement. Worn clutches, faulty solenoids, and low fluid levels are frequent culprits. Strange noises, overheating, and erratic shifting are also common symptoms. These problems can stem from mechanical failures, electrical malfunctions, or inadequate maintenance. Recognizing these issues early is vital to preventing further damage and ensuring reliable vehicle operation.

Understanding How Automatic Transmissions Work

Automatic transmissions rely on planetary gears, hydraulic pressure, and a torque converter to shift gears seamlessly; This complex system is controlled by solenoids and sensors, ensuring smooth operation.

Key Components of an Automatic Transmission

An automatic transmission consists of a torque converter, planetary gears, hydraulic system, solenoids, sensors, and a transmission control module. The torque converter connects the engine to the transmission, while planetary gears provide gear ratios. Hydraulic pressure engages clutches and bands, and solenoids control fluid flow. Sensors monitor speed and pressure, sending data to the TCM, which manages shifts. Seals and gaskets prevent fluid leaks, ensuring smooth operation.

How Gear Changes and Hydraulic Pressure Function

Gear changes in an automatic transmission are controlled by hydraulic pressure, managed by solenoids and sensors. The torque converter transfers engine power to the transmission fluid, which applies pressure to clutches and bands. These components engage specific gears based on speed and load, ensuring smooth transitions. The TCM calculates optimal shift points, while fluid pressure adjusts to maintain performance and efficiency, enabling seamless gear changes without manual intervention.

Common Symptoms of Automatic Transmission Problems

Identify transmission issues early by watching for slipping, delayed engagement, unusual noises, vibrations, fluid leaks, or rough shifting. These signs indicate potential problems needing prompt attention.

Slipping or Delayed Engagement

Slipping or delayed engagement occurs when gears fail to shift smoothly, causing hesitation or lack of power. This can result from low transmission fluid levels, worn clutch packs, or faulty solenoids. Drivers may feel the car stumble or hesitate when accelerating. Addressing these issues promptly is crucial to prevent further damage to the transmission system and ensure optimal performance.

Unusual Noises and Vibrations

Unusual noises and vibrations are common indicators of transmission issues. Humming, buzzing, or whining sounds may signal worn bearings or faulty planetary gears. Vibrations during acceleration can indicate misaligned or damaged components. These symptoms often escalate if ignored, leading to costly repairs. Identifying and addressing the source promptly helps maintain the transmission’s health and ensures smoother vehicle operation.

Fluid Leaks and Low Fluid Levels

Transmission fluid leaks and low fluid levels are common issues that can severely impact performance. Leaks often occur from seals around the torque converter, bell housing, or pan gasket. Low fluid levels can cause slipping, overheating, or gear engagement problems. Checking the fluid level and condition regularly is crucial. If leaks are detected, they must be addressed promptly to prevent further damage and ensure optimal transmission function.

Gathering Tools and Materials for Troubleshooting

Gathering the right tools and materials is essential for effective transmission troubleshooting. Ensure you have diagnostic equipment, fluid check tools, and replacement parts readily available for a streamlined process.

Essential Tools for Transmission Diagnosis

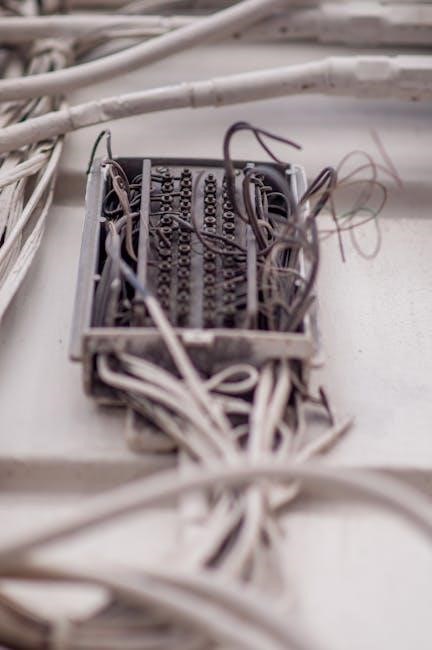

For effective transmission diagnosis, gather essential tools like an OBD-II scanner for error codes, a multimeter for electrical checks, and a pressure test kit to measure hydraulic pressure. A drain pan and torque wrench are crucial for fluid changes and component removal. Additionally, transmission fluid, filter kits, and sealants are necessary for repairs. These tools help identify issues efficiently, ensuring accurate troubleshooting and timely fixes.

Transmission Fluid and Filters

Transmission fluid is vital for lubricating gears, cooling components, and maintaining hydraulic pressure. Low fluid levels or degraded fluid can cause slipping, delayed engagement, or overheating. Regular fluid changes and filter replacements are essential to prevent contamination and ensure smooth operation. Always use the correct type of fluid for your vehicle and replace the filter during servicing to maintain optimal performance and extend transmission life.

Checking Transmission Fluid

Check fluid level using the dipstick, ensuring it matches the recommended level. Inspect color and consistency for degradation. Low or dirty fluid can indicate potential issues.

Location and Removal of the Dipstick

The dipstick is typically labeled and located near the engine or transmission area. Pull it out gently, wipe it clean with a lint-free cloth, and reinsert to get an accurate fluid level reading. Ensure the vehicle is on level ground and the engine is warm for precise measurement. Always consult your owner’s manual for specific location details, as dipstick positions vary by vehicle make and model.

Interpreting Fluid Color and Consistency

Transmission fluid should be pinkish-red and have a smooth, even consistency. Dark brown or black fluid indicates degradation, while milky or frothy fluid suggests water contamination. Metal particles or grit in the fluid signal internal wear. If the fluid is too thick or thin, it may be the wrong type or degraded. Always compare the color and texture to the manufacturer’s standards for accurate assessment and necessary action to ensure transmission health.

Visual Inspection of the Transmission

A visual inspection helps identify signs of wear, damage, or leaks. Look for cracks, dents, or rust on the transmission case and inspect the torque converter and bell housing for damage or excessive wear.

Identifying Signs of Wear or Damage

During a visual inspection, look for cracks, rust, or dents on the transmission case, which can indicate structural damage. Check the torque converter and bell housing for signs of excessive wear or damage, such as scoring or discoloration. Additionally, inspect the transmission pan for leaks or dents that may compromise the system.

Examine the transmission fluid for abnormal color or consistency, as this can signal internal wear or contamination. Also, check for loose connections or damaged sensors, which can disrupt transmission performance and lead to further issues.

Inspecting the Torque Converter and Bell Housing

Inspect the torque converter for signs of wear, such as scoring or discoloration, which can indicate overheating or excessive stress. Check the bell housing for cracks, rust, or dents that may compromise its integrity or lead to fluid leaks. Ensure the torque converter is securely attached to the transmission and engine, as any looseness can cause vibrations or disengagement issues.

Examine the spline or mounting surfaces for damage or excessive wear, which can disrupt power transmission. Verify that the lockup clutch engages properly, as failure to do so can cause slipping or reduced fuel efficiency. Additionally, inspect the bell housing gasket and seals for any signs of leakage or deterioration.

Using Error Codes for Diagnosis

Modern vehicles use error codes to pinpoint transmission issues, enabling precise troubleshooting. OBD-II codes help identify problems like slipping gears or low fluid levels efficiently.

Understanding OBD-II Codes Related to Transmission

OBD-II codes provide critical insights into transmission health. Common codes like P0700 to P0899 indicate issues such as faulty sensors, solenoid malfunctions, or low fluid levels. These codes help pinpoint specific problems, enabling targeted repairs and reducing diagnostic time. By understanding these codes, drivers can address issues promptly, preventing further damage and ensuring optimal transmission performance. Regular scanning with a code reader or scan tool is essential for early detection and effective troubleshooting.

How to Scan and Interpret Transmission Error Codes

Scanning for transmission error codes involves connecting an OBD-II scan tool to your vehicle’s OBD-II port; Turn the ignition on, then use the tool to retrieve stored codes. Interpret the codes using a repair manual or online database to identify specific issues. Addressing these codes promptly helps resolve problems like faulty solenoids or sensors. Regular scanning ensures early detection of potential issues, preventing major repairs and maintaining smooth transmission operation.

Troubleshooting Specific Issues

Troubleshooting specific issues focuses on addressing common problems like slipping transmissions and fluid leaks. Identifying root causes, such as worn clutch packs or faulty solenoids, is crucial. Applying targeted solutions, like replacing seals or adjusting pressure, ensures effective repairs. This step-by-step approach helps restore transmission performance and prevents further damage.

Fixing a Slipping Transmission

A slipping transmission can cause poor acceleration and gear engagement. To fix it, start by checking the transmission fluid level and condition. Low or degraded fluid often causes slippage. If fluid levels are adequate, inspect the torque converter for damage or improper engagement. Worn clutch packs or bands may need replacement. In some cases, adjusting hydraulic pressure or replacing faulty solenoids can resolve the issue. If problems persist, professional servicing is recommended to prevent further damage.

Addressing Fluid Leaks and Sealing Gaskets

Transmission fluid leaks are a common issue that can lead to serious damage if left unchecked. Inspect the torque converter, bell housing, and pan gasket for signs of leakage. Replace worn or damaged seals and gaskets promptly. Clean the area thoroughly before reinstalling components. If leaks persist, consider using a high-quality sealant or consulting a professional. Regular maintenance can prevent future fluid-related problems and ensure optimal transmission performance.

Advanced Troubleshooting Techniques

Advanced troubleshooting involves testing solenoids, sensors, and the planetary gear system. Specialized tools and technical knowledge are required to diagnose complex issues accurately and efficiently.

Testing Solenoids and Sensors

Testing solenoids and sensors involves using multimeters and scan tools to measure electrical resistance and voltage. Faulty solenoids may show open or short circuits, while sensors might provide incorrect data. Replacing damaged components and recalibrating the system ensures proper transmission function. Regular testing helps prevent unexpected failures and maintains smooth gear transitions. Always refer to the manufacturer’s specifications for accurate diagnostics and repairs.

Inspecting the Planetary Gear System

The planetary gear system is crucial for automatic transmissions, enabling smooth gear transitions. Inspect for wear, damage, or metal shavings in the transmission fluid. Examine the sun gear, ring gear, and planetary gears for scoring or cracks. Clean or replace components as needed to ensure proper engagement and avoid further damage. This step is vital for maintaining optimal transmission performance and preventing costly repairs.

Preventative Maintenance

Regular fluid changes and filter replacements are critical for maintaining transmission health. Monitoring performance and addressing early signs of wear can prevent major repairs and extend lifespan.

Regular Fluid Changes and Filter Replacements

Regular fluid changes and filter replacements are essential for maintaining automatic transmission health. Transmission fluid lubricates gears and cools components, while the filter prevents debris buildup. Over time, fluid degrades and filters clog, reducing efficiency. Replacing them every 30,000 to 60,000 miles ensures optimal performance and prevents premature wear. Clean fluid and a fresh filter help maintain smooth gear shifts and prevent overheating, extending transmission lifespan.

Monitoring Transmission Performance

Monitoring transmission performance is crucial for early detection of potential issues. Regularly check for signs like slipping, delayed engagement, or unusual noises. Ensure transmission fluid levels are optimal and look for dashboard warnings. Scanning for error codes using OBD-II tools can reveal hidden problems. Consistent oversight helps prevent major repairs, ensuring smooth gear shifts and reliable operation. Regular checks keep your transmission running efficiently and prolong its lifespan.

When to Seek Professional Help

Seek professional help when facing complex transmission issues beyond basic troubleshooting, such as internal mechanical damage or advanced electronic faults requiring specialized tools and expertise.

Recognizing Complex Issues Beyond DIY Repair

Complex transmission issues, such as internal planetary gear damage or mechatronic system faults, often require specialized tools and expertise. If you encounter symptoms like erratic shifting, solenoid malfunctions, or severe fluid contamination, it’s crucial to consult a professional; DIY attempts on such issues can lead to further damage, emphasizing the importance of recognizing when expert intervention is necessary for a reliable and safe repair.

Choosing the Right Repair Shop

Selecting a reputable repair shop is vital for effective transmission troubleshooting. Look for shops with expertise in automatic transmissions, qualified technicians, and a solid reputation. Check online reviews and ask for referrals to ensure reliability. A trustworthy shop will provide clear estimates, explain repairs thoroughly, and use genuine parts. Prioritizing quality service ensures your transmission issues are resolved efficiently and safely, avoiding future complications.

Wrapping up this guide, effective automatic transmission troubleshooting involves early issue identification, regular maintenance, and knowing when to consult professionals, ensuring optimal vehicle performance and longevity.

Effective troubleshooting starts with checking transmission fluid levels and condition. Identify symptoms like slipping, noises, or leaks. Use OBD-II codes for diagnostics. Perform visual inspections and test components like solenoids. Address issues promptly, from fluid changes to sealing leaks. Regular maintenance, such as filter replacements, prevents many problems. Know when to seek professional help for complex issues beyond DIY repairs to ensure long-term transmission health and reliability.

Final Tips for Maintaining Transmission Health

Regular fluid changes and filter replacements are crucial for maintaining smooth transmission operation. Monitor for early signs of wear, such as slipping or unusual noises. Avoid extreme driving conditions and ensure proper cooling. Keep the transmission clean and inspect for leaks. Stay updated with manufacturer guidelines and consider professional servicing for optimal performance and longevity of your automatic transmission system.

Leave a Reply

You must be logged in to post a comment.